LVL / Laminated Veneer Lumber/Pallet Packing LVL

| Product name | LVL / Laminated Veneer Lumber/Pallet Packing LVL | |

| Size | Witdth: up to 1250mm ;Length: up to 8000mm | |

| Thickness | within 150mm | |

| Core | Poplar,Pine or as client's request | |

| Glue | WBP,MR,E1,E2,E0,F4 | |

| Packing | Export Standard Package (Pallets + Steel Strip) /Or According to customers' requirements | |

| Quantity | 20GP-25M3/ 40HQ-55M3 | |

| Payment | T/Tor L/C at sight | |

| Delivery time | Within 15days after receiving deposit or Original L/C at sight | |

| Usage | Package, Furniture, Construction,Decoration | |

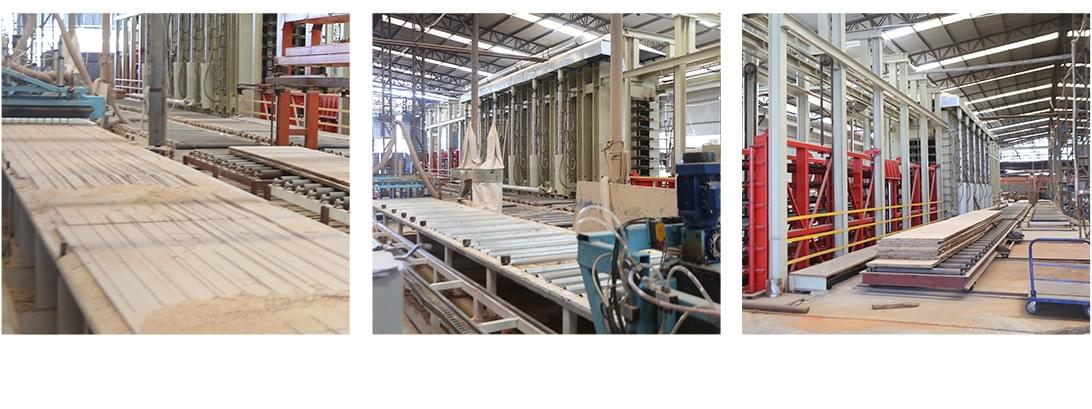

LVL PRODUCTION PROCESS:

STEP1: Cut the log to size.

STEP 2: Peeling the Log to the veneer.

STEP 3: Drying the Veneer.

STEP 4: Grading the Veneer. A, B, C.

STEP 5: Gluing the veneer.

STEP 6: Laying the veneer.

STEP 7: Hot pressure.

STEP 8: Sanding the core.

STEP 9: Cutting to size.

STEP 10: Packaging.

Advantage of LVL / Laminated Veneer Lumber/Pallet Packing LVL:

LVL product has many advantages over sawn milled lumber:

- LVL can be made from various veneer materials poplar, pine, acacia, eucalyptus, rubber, …

- LVL can control the specification: LVL can be produced in almost Thickness, Width, Length, Moisture Content, Uniform. The length of the LVL is not dependent on the log size, due to the manufacturing technique

- LVL is a high strength, but very lighter than sawn timber. Lower price.

- Using wood resources efficiently.

1) Inner packing: Inside pallet is wrapped with a 0.20mm plastic bag.

2) Outer packing: Pallets are covered with 2mm package plywood or carton and then steel tapes for strengthening.

Application of LVL / Laminated Veneer Lumber/Pallet Packing LVL:

1. It can be used for pallet. Due to the hot pressing and formaldehyde, it don't need fumigation

2.The pine LVL can be used for scaffold board. It has high strength.

3. It can be used for sofa frame and other furniture, decoration.

4. It can be used for Door frame