When purchasing film-faced plywood for construction, there are several key factors to consider to ensure that the selected plywood meets your project requirements and provides optimal performance:

1、Material and Quality

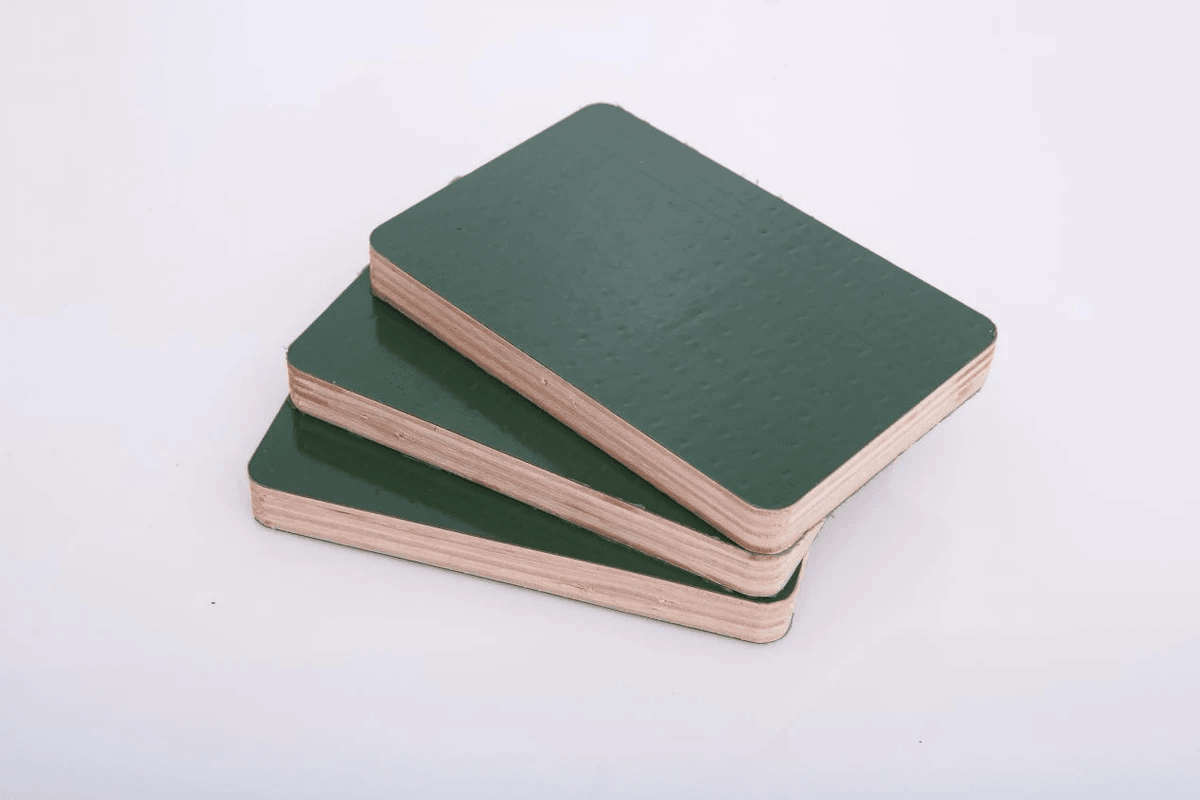

The material of the film-faced plywood directly affects its durability and performance. High-quality plywood should be made from strong and durable wood, such as eucalyptus, poplar, or pine, with excellent load-bearing capacity. Choosing durable plywood can enhance construction safety and ensure the plywood remains in good condition even after multiple uses.

2、Size and Specifications

Ensure that the dimensions and thickness of the film-faced plywood match the specific requirements of your project. Standardized sizes help reduce material waste during construction and improve assembly efficiency. Additionally, consider the weight of the plywood—while it should be sturdy enough, it also needs to be lightweight enough for easy handling and installation, reducing labor demands.

3、Standards and Certifications

It is crucial to choose film-faced plywood that complies with relevant quality standards and certifications. For example, ensure the plywood is certified by a quality management system (such as ISO certification) and has environmental certifications. These certifications guarantee product quality and safety while minimizing environmental impact, contributing to the sustainability of the construction project.

4、Supplier Reputation and Service

Partnering with experienced and reputable suppliers adds extra assurance to your project. Reliable suppliers typically provide high-quality after-sales service and technical support, ensuring any issues encountered during construction can be resolved quickly. Timely communication and response can prevent unnecessary delays in the construction process.

5、Cost and Value for Money

While price is an important factor when choosing film-faced plywood, it should not be the sole consideration. More importantly, weigh the quality, durability, and additional services provided by the supplier to choose the product with the best value for money. Higher upfront costs may result in greater long-term benefits due to the plywood's higher reuse rate, consistent quality, and reduced maintenance expenses.

In summary, when purchasing film-faced plywood, it is essential to consider the material quality, dimensions, certifications, supplier reputation, and cost-effectiveness. This comprehensive approach ensures that the plywood will meet your project requirements, support smooth construction, and maximize economic returns.