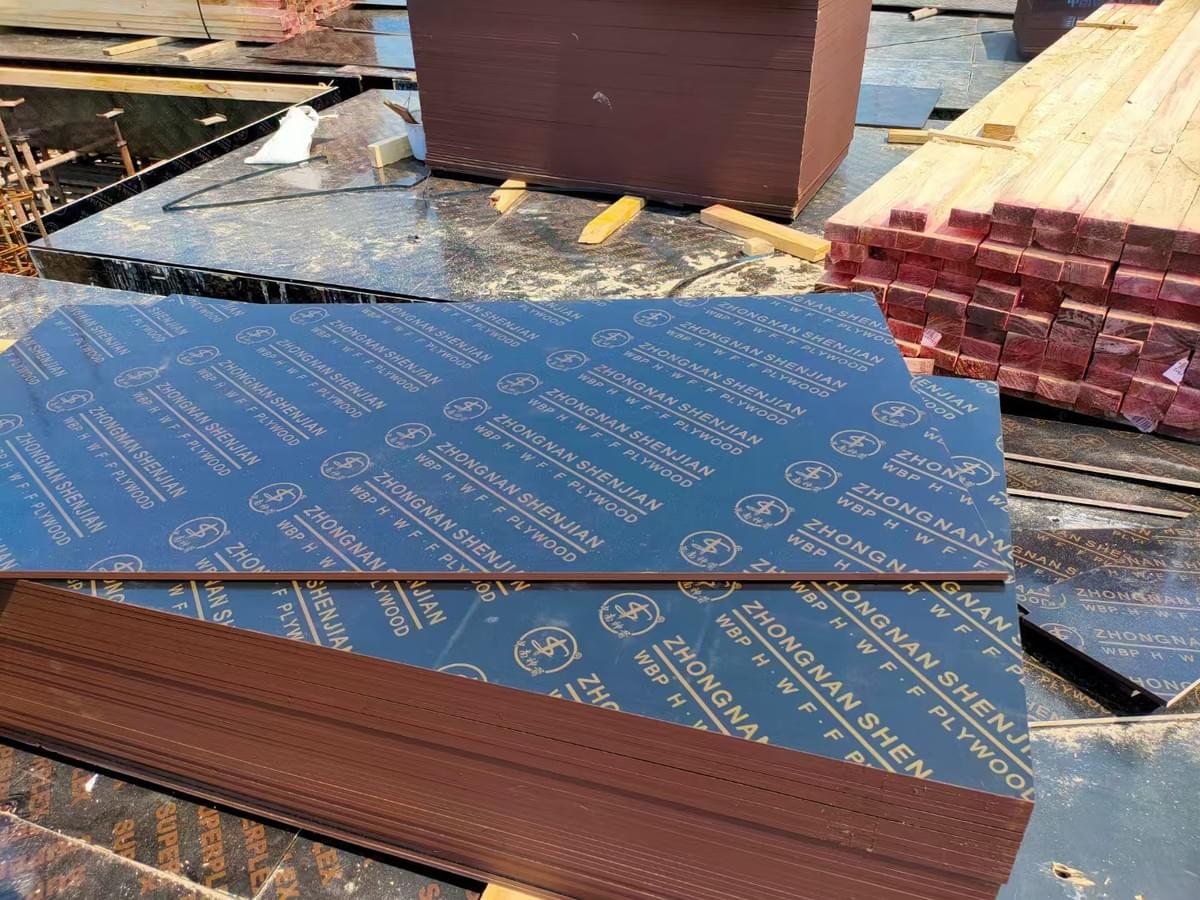

Why Film Faced Plywood Dominates Modern Construction?

- Film faced plywood has revolutionized concrete forming with its unique triple-layer advantage:

- 🔥 Durable Phenolic Film - 120g/m² waterproof coating withstands 50+ reuses

- 🌧️ Weatherproof Core - High-density eucalyptus/poplar hybrid composition

- 💪 Structural Integrity - 18mm thickness maintains <1% deformation under 30kN/m² pressure

5 Critical Specifications for Film Faced Plywood Selection

Project-Specific Film Faced Plywood Solutions

1. High-Rise Building Formwork Systems

Opt for 18mm black film faced plywood with 9-layer cross-laminated cores - proven to reduce concrete honeycombing by 63% in Shanghai Tower-type projects.

2. Bridge & Tunnel Shuttering

Our anti-slip brown film plywood features enhanced flexural strength (≥30MPa) - successfully used in Yangtze River Bridge construction with 28 reuse cycles.

3. Cost-Effective Residential Projects

15mm red film plywood delivers optimal 10-12 reuse cycles - cuts formwork costs by 40% vs traditional timber.

Zhongnan Shenjian's Quality Assurance Process

- As ISO 9001-certified manufacturers, we implement 6-stage quality control:

- Core Veneer UV Drying (≤8% moisture)

- Automated Glue Spreading (380g/m² adhesive)

- 140°C Hot Pressing (25kg/cm² pressure)

- Film Lamination Precision Cutting

- Edge Sealing with Waterproof Paint

- 48-Hour Load Testing

2024 Global Price Analysis + Custom Solutions

Get our latest film faced plywood price list (FOB Shanghai) for:

- Standard 1220×2440mm panels

- Custom Sizes up to 1500×3000mm

- Specialty Treatments: Anti-fungal, Fire-retardant, Cold-resistant (-30°C)

Why 3800+ Contractors Choose Zhongnan Shenjian?

✅ 220,000m² Annual Production Capacity

✅ 72-Hour Global Shipping from 8 Strategic Warehouses

✅ 15-Year Expertise in Tropical Climate Solutions